Demo sites

Four demo buildings showcase: the RE4 solutions for new construction in two different climatic zones (Spain and UK) and the RE4 strategy for the disassembly and reuse of materials and structures from dismantled buildings, the RE4 solutions for refurbishment (Italy), the replication potential outside EU (Taiwan).

Madrid (Spain)

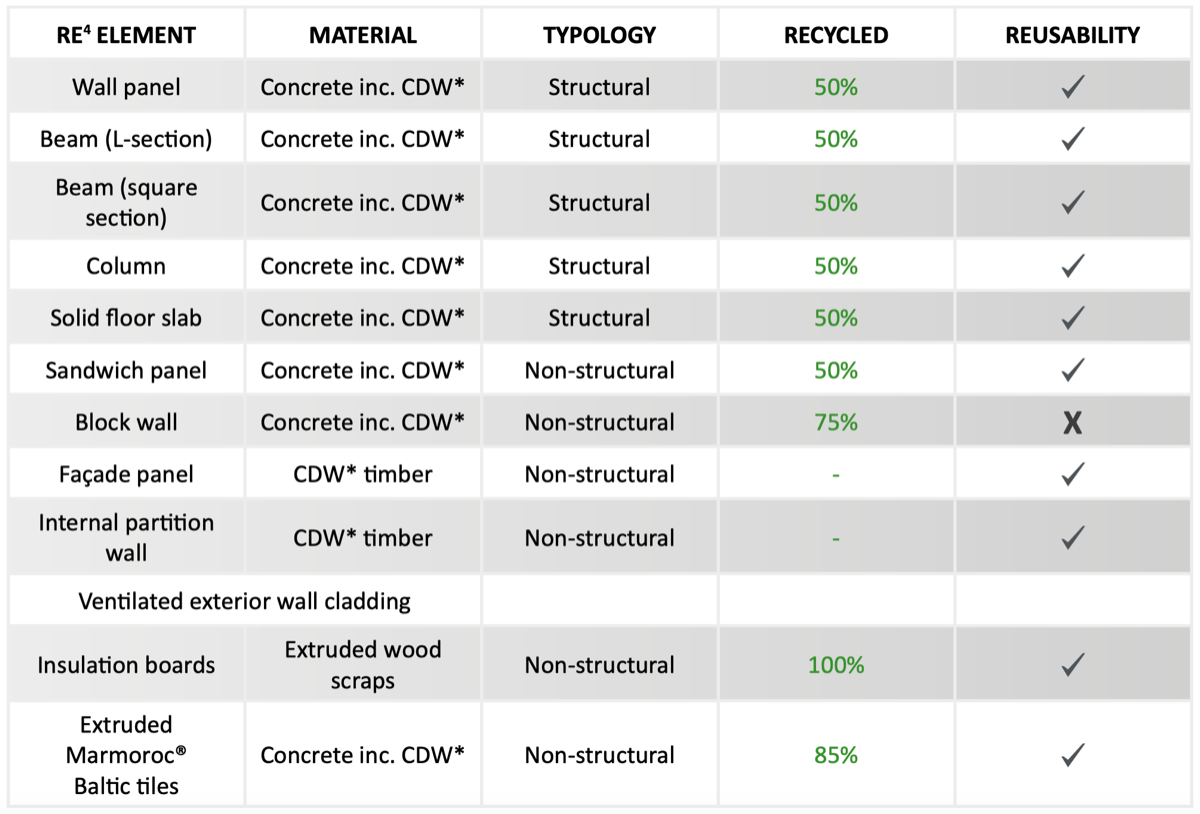

ACCIONA is in charge of the new construction demo building assembly and dissasembly. This demo was designed as a two-storey building with a precast concrete frame of a single column and four beams with a set of bearing and non-load bearing prefabricated wall (façade) elements. The Prefabricate elements & components are incorporating CDW with replacement rate of 50 to 100% CDW.

An additional reference demo building (same geometry and volume) was built for comparison.

Construction/assembly times:

-

14 days - RE4 prefabricated building

vs

-

36 days - Reference buiding

Find more photos in the gallery (COMING SOON)!

Watch the timelapse video of the dissasembly HERE!

Watch the timelapse video of the construction below!

Toomebridge (UK)

Creagh is a leader in the EU industry for production of innovative concrete products (mainly precast and prestressed). In the Project, they are in charge of production of RE4 refabricated components and their assembly into demo building.

Creagh is responsible of building the prototype at their facilities in Northern Ireland (Toomebridge), as the cold climate scenario and monitoring the performance in terms of energy efficiency.

Ground floor wall panels were erected in November 2019. One more level of build to go!

Find more photos in the gallery!

New construction building

Prefabricated energy-efficiency building concept / Calculated U-value= 0.20 W/m2k

Designed as a two-storey building using a panelised fastrack precast system with hollow-core RC slabs spanning the full width of the building and supported into loadbearing prefabricated sandwich panels on the perimeter (façade elements).

Designed for easy and cheaper assembly.

Saving of circa 40% overall time in construction compared with reference buildings built with common construction techniques used in the UK (cast in place concrete structure and brick walls).

Benevento (Italy)

The Department of Engineering of University of Sannio disposes of an experimental station for testing different solutions for the building envelope under real weather conditions, using data analysis, system identification and time-series-analysis techniques.

The lab is located in Benevento City, in south Italy. It has a typical Mediterranean climate, characterized by warm to hot, dry summers and mild to cool, wet winters.

Under the scientific supervision of Eng. Rosa Francesca de Masi, the laboratory is used for different activities that may be classified as:

Experiments in the Energy Efficiency in Building for research projects.

Collaboration with and services for building materials and component manufacturers.

Experimental support for preparation of standards and regulations.

One test-wall of the laboratory has been prepared for the integration of RE4 elements.

The selected elements are: insulating wood boards, 14 cm thick, and extruded coloured concrete tiles from CDW, 2.5 cm thick. Due to the installation of vertical and horizontal steel rails an open joint ventilated façade has been realized, in which the extruded tiles are the cladding system. The air cavity, with the horizontal holey rails, about 10 cm thick.

Some preliminary results have allowed to highlight: the great insulation effect of the wooden panels and the good behaviour of tiles from CDW as a cladding system of a ventilated façade. A long-time monitoring will bring valid results for defining the in-field thermal and hygrometric behavior about this configuration of open joint ventilated façade and its incidence as a passive technology for improving the energy performance of building envelope in Mediterranean climate.

Watch the timelapse video of the ventilated façade installation

Taiwan

Refurbishment

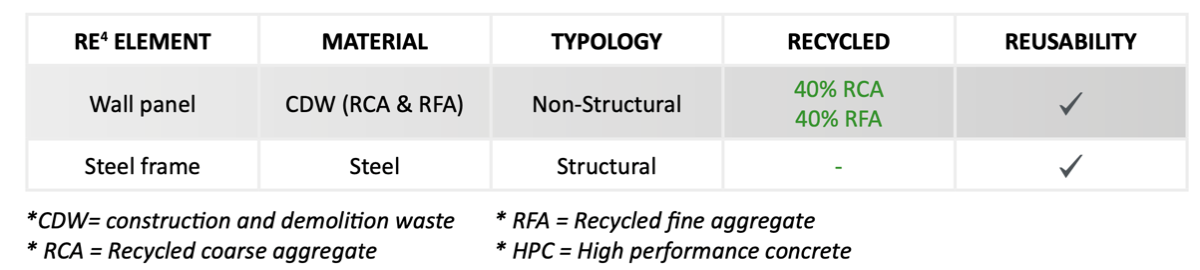

New Prefabricated CDW-HPC panels

Designed for easy assembly (reversible structural connections)

Designed to protect existing structures against earthquakes and Typhoons

Prefabricated panel incoporating CDW (replacement rate at 40% by volume for both RCA and RFA)